3D Laser Measurement Technology

Vision systems of the future

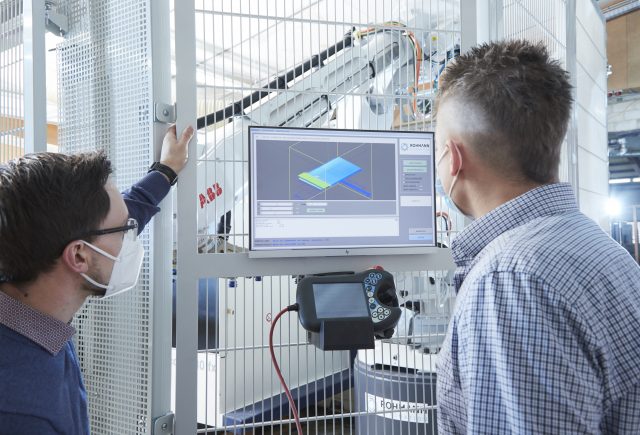

We supply 2D and 3D laser measurement technology for robot systems for various industrial applications. A typical application is the automatic position detection for the removal of components on pallets or grid boxes with robots. Furthermore, our systems are used for quality control.

Turnkey complete systems and integrable individual systems in the field of position detection and robot depalletising

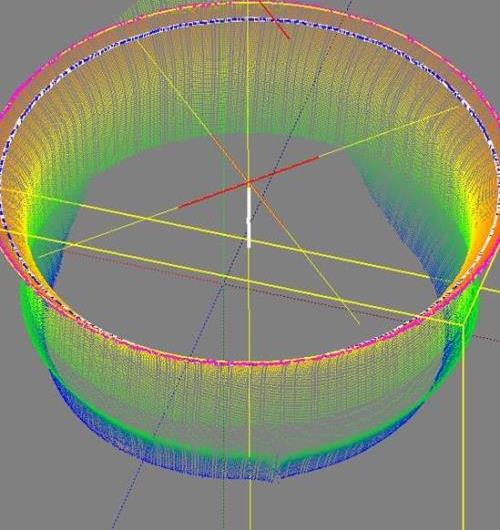

-depalletising of boxes, cartons, blisters, bags, castings, barrels, buckets, canisters by means of scanners and robots

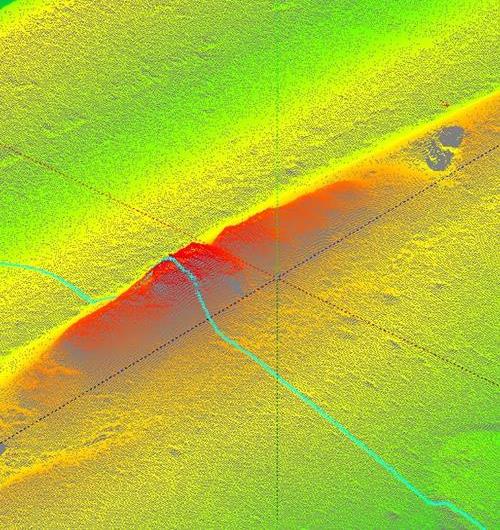

As a rule, a PLC or a robot is the higher-level controller of the following applications. Communication between the 3D evaluation PC and the PLC / robot takes place via ProfiBus, ProfNet, Ethernet TCP/IP, CAN bus, DeviceNet or RS232. The scan frequency is typically 330 Hz, with an angular resolution of 0.125°. Alternative scan frequency / angular resolution is 270 Hz at an angular resolution of 0.10 deg.

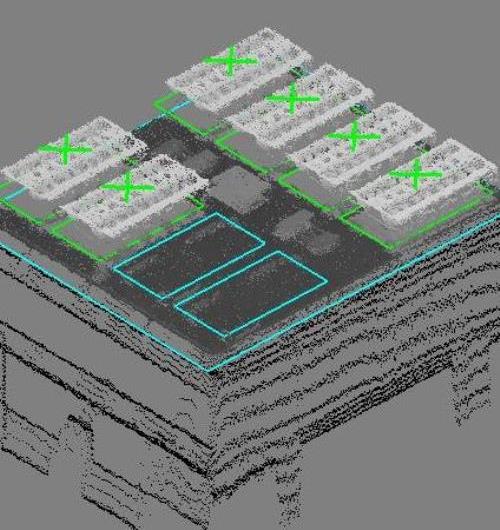

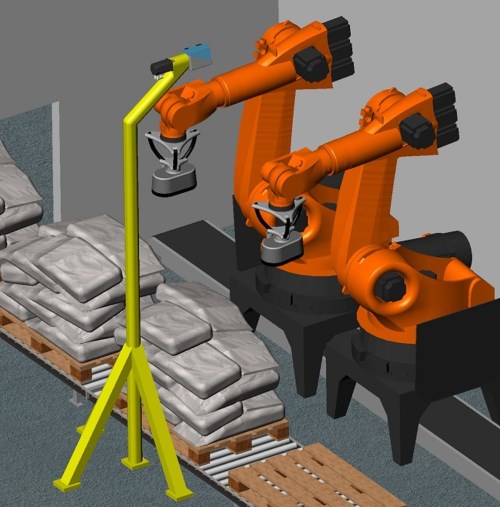

Application example: Depalletising from the stack using a robot

The objects to be depalletised can be round, oval or asymmetrical. The height is 50 to 150mm. The contour is taken from a CAD file. This CAD file contains further information about the object such as gripping points, gripper type, gripper setting and gripping angle.

The workpieces are stacked in up to 10 layers with a position tolerance of ± 300 mm. Depending on the contour, twisting is possible.

The scanner is located in front of the pallet on a linear axis. Each time a workpiece is removed by the robot, a scan is performed.

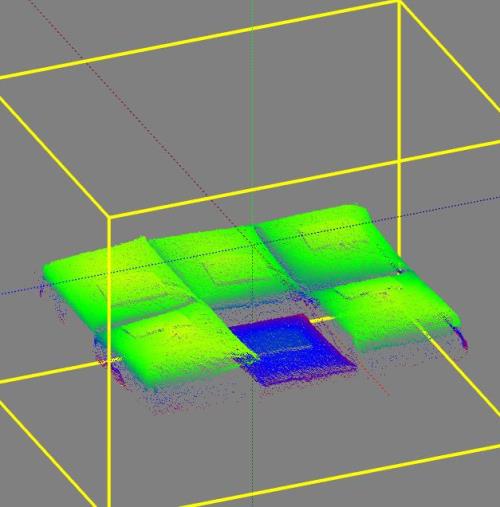

Position tolerance of the objects +/- 300 mm

Twisting objects : +/- 45 Grad

Accuracy X / Y / Z : +/- 2 mm

Linear axis speed : 1000 mm/s

Duration of measuring cycle incl. evaluation : 700 ms

Other applications:

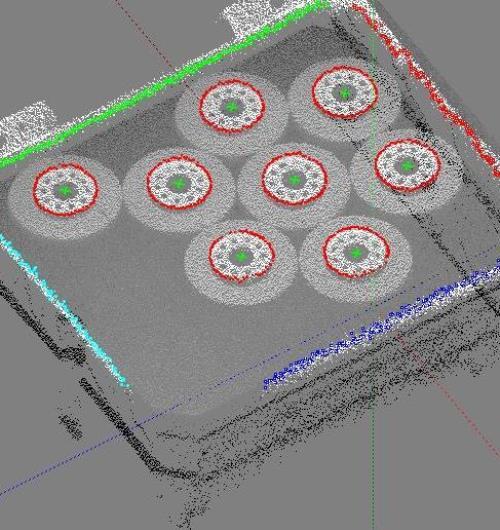

Bin picking - Reach into the box

Robot systems with 3D laser scanner

Applications - The ideal solution for every requirement